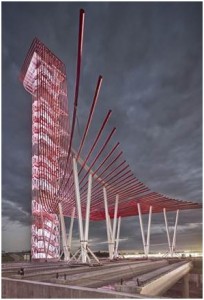

Innovative Design in Engineering and Architecture with Structural Steel (IDEAS2) awards are sponsored by the American Institute of Steel Construction in recognizing projects where structural steel has been utilized in an innovative manner. This year the winners were chosen from nearly 100 submissions from architectural, engineering and construction firms throughout the U.S. This year Circuit of the Americas (COTA) Observation Tower won in the category for projects less than $15 million. The COTA is a 3.4 mile motor racing circuit, the first purpose-built F1 track in the U.S. that is located just outside of Austin TX. The land mark 251 foot tall observation tower was designed by Miro Rivera Architects to give spectators unrestricted views across the racetrack’s twisting bends. The platform (which has a glass floor) provides a 360 degree panorama view of the circuit and has a capacity for 10,000 spectators.

The circuit of the Americas observation tower won the award because it combines creativity, economic and technical achievement through the use of structural steel. The observation tower is very creative in how it uses a veil like structure made out of 18 bright red closely spaced HSS 8.625” OD structural pipe that are curved running down the full height of the tower. The pipes act as a canopy for both the platform and the stage below. The design of the curved pipes was inspired by the visual imagery of sports cars and movement. The red pipes running along the tower mimic the streaks of lights trailing racecars at night time. While ostensibly an architectural feature, the veil also serves as an outrigger column for lateral load resistance via a series of struts and rods that connect it to the main tower. The tower contains approximately 385 tons of steel. The observation tower also had a technical achievement through the use of fully connected Tekla Structures program.

Due to the tight 10 month time frame from owner approval to race day, the complex tower structure design had to be conveyed to the fabricator so they could erect the canopy without confusion. Generally in the steel fabrication construction industry paper drawings are delivered to the steel fabricator to interpret and build, but this case they were able to bypass this step and print shop drawings directly from the model. To increase efficiency and reduce cost of bending each 8 inch steel pipe to the architects initial drawings the program helped work with a bender roller to break large radii into segments. There were a total of 70 curved 8” sch 40 pipes that start out at a tight 96” centerline radius and then get a slightly looser 360” radius before opening up to a large 1,349” radius at the bottom of the tower. The fabricator worked directly with a detailing service to electronically transfer the model into detailed fabrication shop drawings that showed the pipes in different curved sections. The construction manager, Austin Commercial, estimated that the integrated delivery process saved three months over a more conventional process. COTA is more than just a racetrack; it has become a major economic driver in Central Texas. On their website they state that from October 2013 to September 2014, COTA brought in $900 million to the Austin metropolitan area ($731 million for events and $166 million attributed to operations). During that time COTA hosted six motorsports, 18 concerts, 110 track rentals and other events that helped create 9,100 jobs through annual activities and operations.