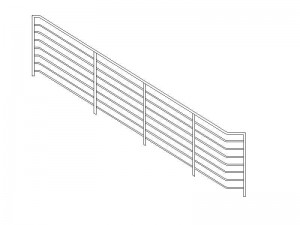

A miscellaneous and ornamental iron shop needed 160 pieces of pipe to be bent for the top and bottom transitions of a staircase. Bending this pipe eliminated 160 welds. And each weld would have required miter cuts, grinding, and attention to avoid sharp corners and irregularities.

Using rotary draw bending with mandrels, Chicago Metal rolled 140 pieces of Schedule 40, ¾in pipe to a 4in center-line radius with 32 degrees of good arc and a variety of tangents at each end.

Using the same method, the company rolled 20 pieces of Schedule 40, 1-1/2in pipe to a 4in center-line radius with 32 degrees of good arc and a variety of tangents on each end. These sections were for the rails above the actual hand rail.

Rotary draw bending of pipes produced smooth, uniform, attractive bends which will become component parts of the stairway.

For more information, contact the Stairway Manufacturers’ Association (SMA) which strives to be “the greatest resource of knowledge and tools contributing to . . . the stair industry.”