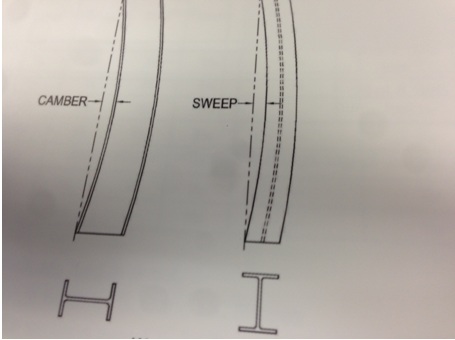

When we are talking about metal bending a camber denotes a curve in the vertical plane (hardway bending) and a sweep denotes a curve in the horizontal plane (easyway bending). Pertaining to steel structures (beams, Channels, Tees, Rails, Angles, and Tubing) camber applies to the curve about the strong axis, and sweep applies to the curve about the weaker axis of the member.

A common way to put a camber or sweep in steel is to cold roll that product in a pyramid style three roll section bender. The rollers push the stress in the steel product past the yield point that will then produce a permanent strain. For cambering this will produce a uniform curve that is ideal in counteracting the effect of uniform loading. For example, cambered beams may offer superior support in a bridge by reducing any sag or downward deflection from the weight of an asphalt road. One might put a sweep in a beam to improve the aesthetics of the project. A sweep can enhance the appearance of a particular structure greatly, without compromising its function. For example, a canopy may be supported by a beam with a sweep that creates an edge curve. Adding a sweep or camber in a member will increase its yield and tensile strength.

The difference between a camber and sweep versus bending and rolling is that a camber and sweep have a rather small mid-ordinate rise, say 1/4 to 2 inches over 40ft, while bending and rolling have large and small radii, say 2ft radius to 300ft radius. The terminology has a lot to do with how a detailed fabrication drawing is drawn. For example, if a rectangular tube has a sweep the drawing will be detailed with a 2-inch rise on a 20ft chord, but when it is curved the easyway it will be detailed showing a 300ft radius with 20ft good arc. Both examples given will produce that same curvature but are detailed differently.