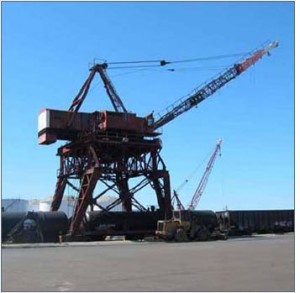

Heavy rolled wide flange steel beams provide a strong yet simple mounting surface for circular rails of a Whirley Crane. Whirley Cranes are, by definition, free to rotate 360 dgrees while loading and unloading.

Two large rings were rolled the “easy way” (y-y axis) and installed using W24 x 192 beams: a 32ft diameter outer ring and a 14ft diameter inner ring.

“The Inner Ring was the challenge,” says project manager Dan Wendt. “A very wide 13inch flange to a 7ft radius could have dished, tilted out of flat, or even rippled without special tooling.

The customer, a crane repair and re-manufacturing company, was very pleased with the results. “The flatness of the flanges created a great surface for us to mount our 175# ASCE crane rails on to.” In this situation, the rails were re-used from the original crane, but Chicago Metal Rolled Products can curve rail if needed.

A previous design mounted the rail on a built-up box girder, but under the weight of the crane and with the pressure applied at the center of the box girder, the rail support often distorted and had to be replaced. With the new design, the crane rail sits at the center of the beam web directly above the web for maximum support.

These types of cranes are rarely made anymore, but nostalgia is keeping them alive. During World War II, the Kaiser shipyard in Richmond, Virginia, produced 738 war ships, still the current record. Dozens of Whirley cranes greatly improved the efficiency of the production of these ships. Richmond’s Rosie the Riveter National Historic Park has preserved one of the original cranes for history.