In honor of the 4th of July holiday celebrating American independence, I decided to take a look at one, if not the best, example symbolizing the spirit of this national holiday. The Statue of Liberty is a national monument known around the world which was first gifted to us years ago by the country of France. This symbol of enduring freedom has been featured across countless media outlets as one of the most iconic locations in America.

Neatly enough, there are many examples of curved metal in the monument. Lady Liberty herself is composed of copper which has aged to its distinctive green coating over time due to the saltwater exposure. On the interior however, steel is used for its lightweight properties to form the structural supports. The massive iron pylon and skeletal framework of the statue were designed by Alexandre Eiffel who is of course also famous for the Eiffel Tower in Paris, France, while Sculptor Frederic Auguste Bartholdi was the artist commissioned to design the sculpture. The design of the exterior curved sculptural surfaces was created using a technique called ‘repousse’ which involves hammering sheet metal inside molds. Because this would be lighter than cast metal, repousse was necessary to lessen the weight of the pieces as they were shipped from France to the USA.

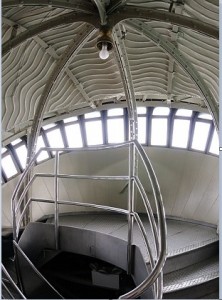

The outside of the sculpture includes 31 tons of copper, standing 305 feet tall, with an additional 125 tons of steel in the framework. The refurbished interior of the statue includes a helical staircase which takes visitors up through the guts of the statue to the iconic viewing area in the crown upon Liberty’s head. The staircase features helical stair stringers and matching helically curved handrails, which must have posed an interesting challenge for installation. Due to being installed on the inside of the somewhat cramped structure, many of the construction tools we think of would be impossible to use. Yet, the end result allows individuals to make the trek up to take the breathtaking view from the top.