Drafting is the creation of technical drawings that visually communicate the physical and functional attributes of a design via a standardized drawing and annotative style. All drawings created by a draftsman should be similar in appearance and therefore easily interpreted, yet this is not always the case. Often, symbols are misused and information points to incorrect parts of a drawing requiring the need for revisions. Revisions help increase the accuracy of the drawings, but sometimes things slip through the cracks and sloppy drafting gets through to the people who need to use them for manufacturing.

A construction drawing set is the end product of all the drafting and design done between architects and engineers. The purpose of these drawings is to show how the components of a design come together and their relative orientations, not how to manufacture custom curved steel structures.

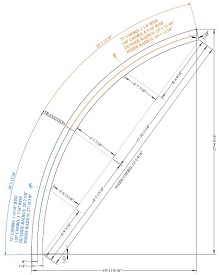

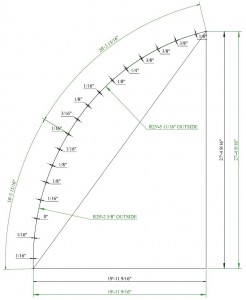

Manufacturers of curved steel can still utilize construction drawings for the purpose of production by deriving new information from what is already provided. By re-drafting the steel sections of interest, the pertinent information for production can be obtained rather quickly. When re-drafting, the draftsman needs to make sure that the general dimensions of the steel, for construction purposes, remain the same. Once this has been achieved, any detailed dimensions regarding arcs and tangents must be double checked to ensure that they truly represent what is shown in the design. Sometimes the visual and dimensional data from the designer will not match up, and its best to catch this early to avoid problems down the road. The design professionals may know what they want, but the manufacturers know what they need, so suggesting a small design change can be the key to a project’s becoming a success or a failure. As long as a margin of error within a fraction of an inch is acceptable, something as small as simplifying an arc from infinitely many radii down to two or three can still yield perfect results and a more than satisfied customer.

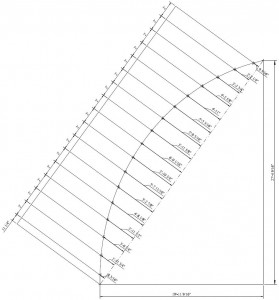

When it comes down to forming the steel via bending or rolling machines, machine operators require an additional set of data for checking and verifying that the pieces have been made according to design. Information that is not critical to this final stage of production should be removed, and the remaining data should be organized to be legible and easily understood, reducing any chance for confusion. Even going as far as to create templates or simple measuring devices can be a small price to pay to ensure the product meets the customer’s needs and schedule.