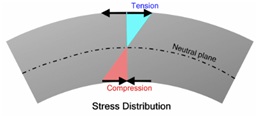

When steel plate is bent, the inside surface of the bend is compressed and the outside surface of the bend is stretched. Somewhere in between lies the neutral axis which is a line in the steel that is neither compressed nor stretched. The tighter the radius the bigger the opposing forces become – bringing up the concept of minimal radius.

The location of this line is key to determining the blank or developed length for bent pieces. Blank or developed length is the amount of material required to make the desired bend. Usually, the neutral axis is slightly closer to the inside of the bend. For practical purposes, it located at half of the thickness for thickness values less than 0.08 inch with a minimal error.

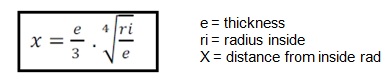

Based on experience, the general equation to find the distance from the inside face to the neutral axis is as follows:

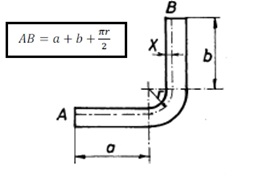

To calculate the blank length of a bent piece, we first have to determine the position of the neutral axis. The developed length of the piece will be the developed length of its neutral axis – in the equation below, we are referring to AB.

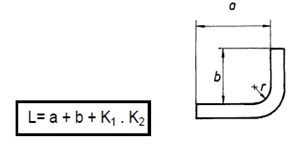

Another way to determine this blank length is using the following equation and tables.

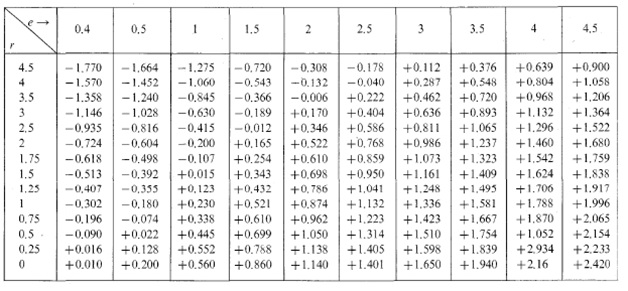

We can find K1 from following table :

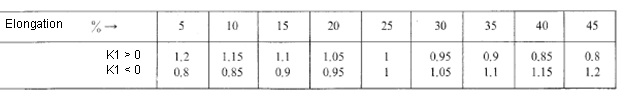

And we can find K2 from the following table:

By calculating and taking into consideration the developed lengthy, a qualified metal bender roller can accurately bend plate to the desired final product. Contact us today for your free plate bending quote.