Most curving of steel discussed on this blog is done on section benders or plate rolls. But curving steel plate through the use of a press brake with radius dies is also done. As the ram presses the steel plate down with a convex die, the plate is pressed into a matching concave die to achieve the desired radius and arc length. Expert machine operators adjust the ram stroke and tooling to compensate for any “spring back” in the forming process.

Of course, press brakes can be used to form 90 degree angles, for example, as well as a myriad of other bends.

A recent job required both radius dies and dies for a sharp bend.

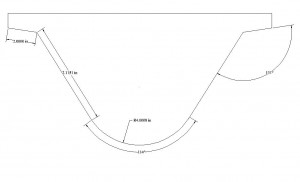

1/4in thick plate was sheared to 25-1/4in wide, 10ft long. Then the press brake was used with a sharp forming die to create a 2in lip the length of the part on both sides. Lastly, radius dies were used to put a 4in radius with straight tangents along the length of the part.

To ensure that all the parts were made correctly, checking templates with the desired dimensions were developed and used in the manufacturing process.

These steel parts will be used as gutters on top of a long canopy. The requirement called for 480 lineal feet so 48pc 10ft long were produced. The canopy is part of CARTS (the Capital Area Rural Transporation System) in Texas.