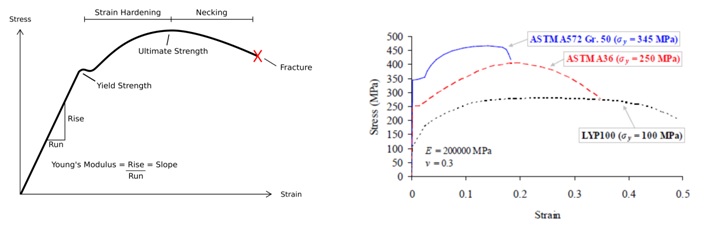

We just produced some very thick and very wide rolled steel cylinders. For this particular industrial application in the chemical industry, the customer required a special grade of plate A572-50 with increased resistance to atmospheric corrosion. The yield strength of the plate was +50,000 psi, much higher than regular A36 steel plate (+36,000 psi). The higher yield directly impacts the amount of force needed to induce permanent deformation in the plate as you can see in following Strain/Stress graphics.

This project for rolled steel cylinders was no easy feat. The plate thickness was 2½ -inches. Each steel plate weighed approximately 17,000 pounds which means high-capacity overhead cranes were required to perform bevel and rolling operations.

A total of three large steel cylinders were rolled with an 8-foot outside diameter. Each rolled steel cylinder was seven feet tall. The cylinders required a double bevel on all four sides, including the seam. Beveling is a sloping surface or edge on the edge of the plate. To bevel the edge of the plate, a plasma nozzle is set up on a semi-automated track that keeps the speed regulated and constant through the operation to obtain a homogeneous and smooth surface.

In the image below, you can see some examples of 2½-inch bevel with different degrees and landings. From top to bottom, the picture shows a plate with double bevel with an unequal degree, single bevel and double bevel with equal degrees.

To ensure the final cylinders were within the required roundness tolerances of 1/8-inch, nine to 10 inches were added to the length of each plate. This extra material was trimmed off after pre-rolling the plate ends.

Once the plate was set on the plate roll machine, with the right length and both ends pre-bent, the machine operator progressively applied pressure passing the plate through the rolls to reach the desired curvature. It was crucial to keep the plate square with the rolls at all times for both ends to match up. If the plate was not square, it would have been tremendously difficult to correct this issue with such heavy plate. Below is a picture of the final rolled steel cylinders.