Bender/Rollers, those companies that specialize in curving structural steel, steel sheet and steel plate, often supply rolled steel and metal shapes to equipment manufacturers as component parts. These original equipment manufacturers (OEMs) turn to Bender/Rollers precisely because their make-or-buy analysis indicates they should buy these parts.

Given that Bender/Rollers will supply many parts to OEMs, what measures or metrics should the Bender/Roller put in place regarding this type of work? Best practice indicates that they should align their performance measures with what customers want. And what the customer wants is almost always quality, service, on-time delivery, and value.

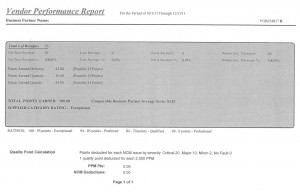

Many OEMs provide suppliers with something like a “Supplier Report Card” or a “Vendor Performance Report.” These, of course, are a direct expression of what an individual customer wants. One such report card measures “Spend” (the cost of the parts ordered), “Line Rejects/Returns,” “Delivery Score,” “Quality Factor,” and “Total Score.” Another measures the number of “On-Time Receipts” and its percentage, the number of late receipts and its percentage, the number of early receipts and its percentage, and the number of orders within tolerance and its percentage. It allocates 45 points for delivery, 10 points for quantity, and 45 points for quality. Ratings of 100-95 are “Exceptional;” from 94-85 “Preferred;” 84-70 “Qualified;” and 69-0 “Probational.”

Most OEMs, however, do not provide suppliers with a report card. Consequently, it is important for Bender/Rollers to maintain their own internal report cards. Again best practice is to measure what the customers want. On-time delivery and quality are metrics that the best companies should be able to track. Service and value may be more difficult to quantify. Service could include requirements such as special packaging, aid in sourcing raw material, and even invoicing correctly. Value is measured in part by the willingness of customers to continue to order parts at a given price year after year.

Manufacturers, of course, measure many other things including machine utilization, sales volume, profitabilility, and the cost of labor and material for a given item. As important and critical as each one of these metrics is, a truly customer-focused organization puts the highest priority on measuring and meeting customer needs and strives to continually improve in the eyes of those customers.