Methods to curve pipe include rotary draw bending with a mandrel on a pipe bender and rolling pipe on a three-roll bender (also called an angle roll, a pyramid roll, or a section bender). For simplicity, let’s call the first method “BENDING” and the second “ROLLING.”

Let’s say you require 5D bends for basketball backboard supports.

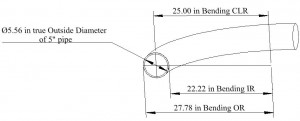

“5D” bend means that the BENDING Radius (Centerline or CLR) = 5x Nominal (name) diameter of the pipe

Typically, these are the limits :

ROLLING standard pipe (sch40): CLR > 5D (5 x dia of pipe) or maybe 3.5D

BENDING standard pipe (sch40): CLR > 3D (3 x dia of pipe) or maybe 2D

5D bends are close to the limit of rolling, so when deciding to roll or bend, the quantity of parts needed to produce can be the deciding factor.

In the situation of 5D bends for basketball backboard supports, bending was a better idea because the customer wanted 50pcs and good control of the tangents.