Often, in the bending and rolling industry, we see requests which push the limitations of tube bending. This can occur in both large and small pieces. Sometimes a project may have been designed without considering the physical effects curving has on the material. In these cases, design plans can occasionally be evaluated and modified with the knowledge of an experienced steel bender.

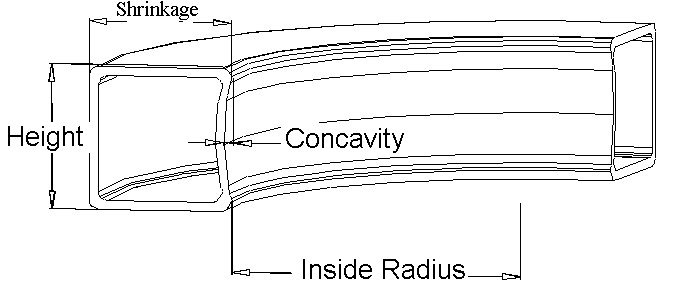

One of the most common examples in tube bending where material shape and size needs to be evaluated is tube cross-section deformation. If you were to be rolling flat material to form a cylinder, the plate rollers are designed to sandwich the material between the rolls, completely and evenly supporting all material under the same stress levels. Even when curving angles, rolling equipment can use dies of different shapes in order to brace the material on the interior and exterior faces, so that pressure is applied evenly. However, when rolling a tube or pipe, the fixed bending dies of the rolling equipment can only form around and support the exterior of the material. This leaves the center of the tube open, and more vulnerable to deformation due to uneven pressure. Tubes can experience concavity, or even changes in overall height or width on particularly difficult bends.

This happens as a result of the rolling dies pressing inward on the tube walls. The reverse pressure from the die on the opposite side of the material also pushes back, but the force does not carry through the hollow space of the tube equally, leading to issues of concavity and the resulting shift in material causes height and width shrinkage/growth if severe enough.

An available option to counteract these efforts is to increase the wall thickness of the tubing to help in lessening distortion issues. In the event that material is architecturally exposed tubing, sometimes any deformation is unacceptable, and in those cases, further accommodations or changes may be required to the design to find an alternative.

[maxbutton id=”1″]