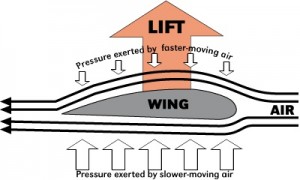

The aviation industry has had a connection with the steel bending and curving industry for many years. Sometimes we take for granted just how important the connection is. It is easy to forget that the exterior of the commercial jets we use for the most frequent flights out there were engineered with very specific curvature in mind. The “Bernoulli Effect” is the principle whereby the air moving over the curved steel surface of the wing travels more quickly than the underside. This creates a lifting force pushing the underside of the wing upward. In addition to the wings, the plane fuselage is covered in curved steel designed to reduce air resistance and improve flight capability by maintaining a high strength to low weight ratio for the plane exterior.

Aircraft hangars are one of the most common sites around airfields where planes are housed. Many of these hangars utilize curved steel roofing structures for their lightweight and sturdy construction. A roof support can be made of lightweight steel beams curved and welded into truss sections which then give the structure a practical application. The curved beams allow for a centrally raised roof, with minimal interior beam support, as opposed to traditional flat construction. Obviously, this is a crucial factor for housing planes with extensive wingspans and elevated tail heights. The use of curved steel beams is a natural and practical use for creating structures with large open floor space. The massive airplane hangar pictured below covers 35,000 square feet, with a ceiling that reaches 43 feet at the center.

Another area where the aviation industry often highlights curved steel construction is for the airports themselves. Many major airports are finding the use of curved steel architecture an integral part of their design plans for expansion. The look of curved steel is modern and fluid, which creates a pleasing and open environment for their thousands of travelers. One such example is the Portland International Airport, highlighted here with a picture from the AISC. The 120,000 square foot steel and glass canopy in this image covers and protects the passenger drop-off area. Given the traditionally rainy nature of Portland, Oregon, having such a magnificent structure is a benefit to keeping travelers dry. The curved steel trusses also support to curved walkways which connect the main terminal to the airport’s parking garages.