When most people in industry talk about rolled and welded products, they are speaking about steel rings or steel pipe. It is true that these two manufactured goods are probably the most common of all rolled and welded products but rolled and welded items could be made from many different structural shapes and in many types and grades of metals.

First let’s focus on the most frequently requested and most common of the rolled and welded family: steel rings. Steel rings are commonly made from formable grades of steel like A36, A572-50 and even A516-70 in the form of steel bars or flats and rounds or square steel sections. The bars/flats can be rolled the hardway or easyway and are more often than not used as, but not limited to, flanges, straps, collars and/or saddles. The welding of these rings is detailed with a joint design and a welding procedure. Stick and MIG are the most common types of welding procedures performed to complete a joint on this type of product. In scenarios where these products will be used in corrosive or high temperature environments, rolled and welded rings may be made from other metal alloys such as 5000 & 6000 series aluminum, 300 & 400 level stainless steel and specialty alloys such as super-austenitic stainless steel like Duplex 2205 or nickel based alloys such as Inconel 625, C276 or AL6XN.

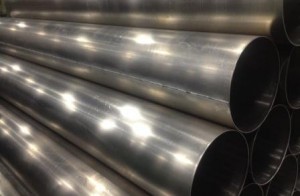

Rolled and welded steel pipe is another product type that is frequently sought after from rolling companies as steel pipe provides designers with excellent strength-to-weight characteristics. Although there are many mills that produce pipe in a wide range of sizes, there is still a need for rolled and welded pipe from rolling companies; the reason being that through purchasing powers, The American Petroleum Institute (API), in combination with industries like the chemical/petrochemical, oil & gas, power process piping, refining, offshore, water, transmission industries as well as vessel fabricators, and pipe contractors dictate what sizes of pipe are produced at tube & pipe mills. Uncommon sizes or “oddballs” are often hard to find either at mills or at service centers. Only when there is enough tonnage requested will a mill produce pipe and tube to an oddball size. This is where a rolling company’s services become extremely valuable.

Rolled and welded steel pipe is used when the diameter and/or wall thickness requires something other than what is a standard mill product. These pipes are made from plate and or sheet and rolled into cylinders or cans in a plate roll or formed by a press brake. Pipes are most frequently produced and ordered in 10ft lengths but can be purchased up to 20ft long from companies with machinery capable of handling the additional length. The seam of the cylinder is beveled according to the joint design and then usually welded through an automated submerged arc welding process. Most rolled and welded plate products are fabricated to ASME code. Once the cylinders or cans are welded complete and tested, they can then be considered and certified as pipe. Most commonly, pipe is made to feed or run gas or liquid from one place to another or from one process to another. Other pipe products are made for applications such as jacket legs and piles for offshore platforms, mooring and breasting dolphins, bridge piles, caissons, tank legs and sign structures, secant pile and combination retaining walls. Rolled and welded pipe is most commonly made from carbon steel plate such as, but not limited to, A36, A572-50 and A516-70. Rolled and welded pipe can also be made from stainless or aluminum alloys where corrosion resistance and temperature considerations need to be accounted for. Rolled and welded aluminum pipe is often requested in 5083-0 cryogenic applications as this alloy holds the best properties for low temperature applications, but 2000, 3000, 6000 & 7000 series aluminum alloys are also used.

Other rolled and welded products include cones or reducers. These products come in concentric, eccentric and offset cones. Materials include carbon steel, aluminum, high strength & abrasion resistant grades, and stainless steel & nickel alloys. Depending on the height, angle and diameters of the cone, it can either be rolled or pressed. Structural shapes such as angles, channels and beams are also called out to be rolled and welded into rings and are often used as stiffeners for large diameter tanks.