When a pipe or tube is called out to be bent to a certain radius, that bend requires a specific set of tooling that will satisfy both the requirements for the size of the pipe or tube being bent and the specified radius called out in the bend design. For example, a 3D bend on a 2″ pipe would mean that the tooling needed would be specific to both a 2″ pipe and a 6″ centerline radius. So, a 1″ pipe bent to a 2″ centerline radius would require completely different tooling than a 1″ pipe bent to a 3″ centerline radius, as well as a 1.5″ pipe bent to a 3″ centerline radius would. With so many different possibilities in combinations of pipe sizes and radii, the amount of tooling a company would need to own in order to satisfy every designed pipe or tube bend is rather immense. With tooling being extremely expensive, in the tens of thousands of dollars range, there has to be some method or strategy that would allow for common tooling to satisfy the bending requirements without changing the overall design or dimensions.

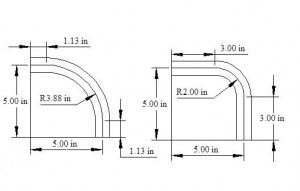

Many companies will only invest in tooling that would be common to pipe or tube bends like the ones listed above: 1D, 2D & 3D. So with bend designs coming in at denominations in between those listed, how are bending companies with limited tooling able to satisfy these bend requirements? In most cases as long as the bend is not designed to snake its way in and out of limited enclosure space, (and that would need to be verified with the design architects/engineers), then the specified radius of the bend is able to be adjusted as long as the overall dimensions of the bend are met. By adjusting the bend radius, tangents coming off of the bend will either need to be shortened or lengthened depending on the overall dimensions.