Because of its symmetrical nature, pipe can be bent to consistent radii with no distortion, but several things need to be taken into account in order to avoid rippling. In part one of this blog post, we discussed why rippling occurs and what material should be used to avoid it. Once the best material has been determined, a pipe bending company must use the right machine, tooling and methods in order to avoid distortion.

Pipe bending techniques include, first, looking at the inside and outside bend radii of the task – this will help identify the best machine and tooling to successfully bend pipe. If the pipe requires a tight bend radius, usually with a radius from 1 to 8 times the diameter of the pipe, then a heat induction, rotary draw or push bending operation with a die matching the shape and size of the pipe should be used. These methods offer the most support.

Bending pipe to any radius 8 or more times larger than the pipe diameter in inches should be able to withstand bending on a section rolling machine with a thick enough wall for stability under opposing compressive and tensile forces.

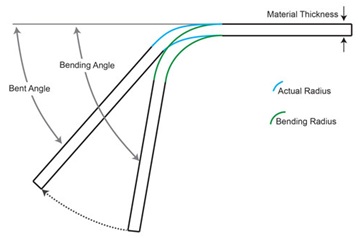

When bending pipe, springback can occur leading to radial growth. To account for this, pipes are usually slightly over bent or bent to a slightly smaller radius than the print or design requires depending on how small the radius is and what material is being used. Steel members with abnormally high tensile and yield strengths require rolling to a much tighter radius than the design requires to achieve the true design radius. This is because you must strain the material more to force it to hold a shape. Typical pipe steel grades and pipe sizes don’t require severe over-bending in most cases to achieve the desired results.

Consulting with a pipe bending company will help determine the best material and pipe bending techniques to use to achieve the required curvature.