Certain projects require bending metal tubing and pipe into a reverse curve that looks like the letter “S” or repeated reverse curves that look like a sine wave. The applications can be for structural steel, for ornamental and miscellaneous metal, and for art. The methods for bending these shapes include three-roll bending, rotary draw bending and a combination of each.

6 x 2 x 0.25 rectangular tubing was curved to a 24ft 0in outside radius with an 8.25ft of good arc (outside) and with a reverse curve on each end rolled to a 12ft 0in radius (inside) with 2.33ft good arc on each end and with +18in tangent on each end. Twenty-eight pieces were curved in this way for a structural steel application. These large radiuses were curved on a large three-roll bender (also called a “pyramid roll,” a “section bender,” or a “profile roller.”)

4in square, aluminum tubing has been rolled into an S shape on a three-roll bender for a miscellaneous and ornamental metal application.

2in square tubing has been bent through the rotary draw bending method (also called “mandrel bending”) to create bike racks for Chicago’s Millennium Park.

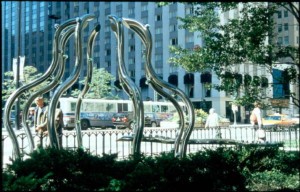

And 2in OD polished stainless tubing was curved by using both a three-roll bender and a rotary draw bender to create art. The result was “Amazon Rising,” a metal sculpture celebrating a new exhibit at Chicago’s Shedd Aquarium.

Having a wide variety of both different sizes of bending machines as well as different types creates the opportunities to successfully bend metal tubing and pipe into reverse curves without splicing. In some cases, expensive weld splices can be eliminated by using reverse curves. And, depending how the metal section is to be bent, curved steel can be made with no straight at the inflection point.