Steel plate or steel sheets are used in angle bending and bending channels. Only very large quantities (5000 feet) can be economically roll-formed. So most parts are formed on a press brake with a vee-die setup. The inside corner radius is typically 1 to 1.5 times the thickness of the material. This would be the “standard” inside bend radius.

However, many designers are specifying large radius corners in their parts for both aesthetics (a smoother rounded corner) and function (avoiding sharp corners). Forming these larger radii requires different tooling sets for each bend radius. Roll curving these large-corner-radius formed parts can be difficult– especially keeping the corner radius intact.

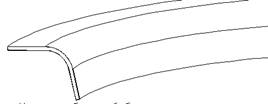

This stainless formed angle is formed with a 2 inch bend radius, and then rolled to a 12 inch radius which is used as a curb bumper for toll booths.

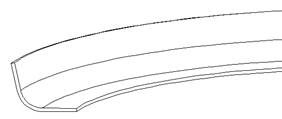

This ¼” shroud is formed to an obtuse angle with a 2” radius and roll curved to a large parabolic curve to match the curvature of a bridge. It will cover the lighting that runs along the arch of the bridge.

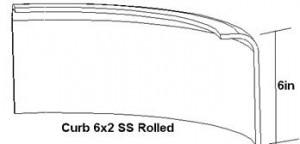

This 12ga stainless channel is formed to a 1.5” radius and then rolled to a 30” radius.

It will be used in metal ductwork as a stainless steel elbow in food processing plant. The large radii prevent materials from building up in the corners.