Circular staircases made of steel have become more popular with owners and their architects for the way they give the illusion of making smaller rooms seem much larger and for the way their free-flowing designs are able to blend with the surrounding architecture to add to the appearance of open space. New facilities as well as existing buildings are livening up the space available by introducing large elaborate grand curved staircases or re-fitting a curved stair to where a straight L or U stair once was. It is in these situations where we find the most difficult of stair stringers to form, ones designed with variable pitch.

In a curved steel staircase with consistent pitch, the tread design is such that the treads are placed perpendicular to the radius/curve of the staircase. All tread lines, if extended to the very center of the staircase’s radius, will meet at the center point of the circular staircase. This gives each tread a specific degree of rotation. If each tread’s degree of rotation is added together, it would give the total degrees of rotation for each complete stringer. The staircase’s plan-view arc length is derived from this calculation. It is also usually the case that the outside and the inside stair stringers both have the same degree of rotation, and that it is the stringers’ differing radii that cause the inside stringer to be smaller in length than the outside stringer. The treads, therefore, are flared with the width of the treads being smaller where they meet the inside stringer and larger where they meet the outside stringer. Each tread of this type of curved stairs should be exactly the same; every tread having the same degree of rotation as the next. This consistency of tread width and degree of rotation causes these types of curved stairs to be considered to be designed with consistent pitch.

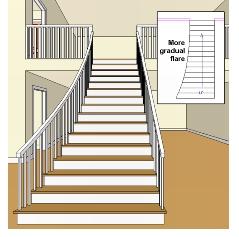

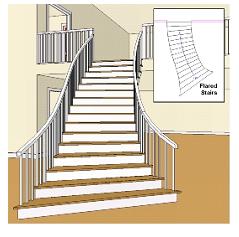

So what happens when the staircase is elliptical, containing multiple radii within one stringer? What if your stringer is a combination of a circular staircase and a straight staircase, usually referred to as a sweeping stair? What does this do to the flow of the staircase? What does this do to the consistency of tread width and degree of tread rotation? Most importantly, what does this do to the stair’s pitch and how does this affect the steel bending process to produce the stringers?

If stair stringers for staircases such as the ones depicted above were formed using the same techniques and methods that were used on your basic circular staircase, you would find that you wouldn’t be able to fit your treads in their proper location and at the worst, you would see that some treads wouldn’t even be located on the stringer when they are fit.

If stair stringers for staircases such as the ones depicted above were formed using the same techniques and methods that were used on your basic circular staircase, you would find that you wouldn’t be able to fit your treads in their proper location and at the worst, you would see that some treads wouldn’t even be located on the stringer when they are fit.

As mentioned previously a stringer formed with consistent pitch has all of its treads at the same width, but when a staircase is designed with a flare or is parabolic/elliptical, this causes the tread width to differentiate at different points along the stringer. This difference in tread width is the reason why these types of staircases are designed with variable pitch, meaning that as each stringer curves helically upward toward the landing, the pitch at which it is angled is changing as the stringer proceeds up along its length.

As mentioned earlier, most of these stairs are very large grand curved staircases in very large commercial projects, and the materials used to support these structures are rather large themselves, ranging from hollow structural tubing, to beams, to channels. Curved stringers formed with variable pitch are extremely difficult to accurately form and usually require a dedicated engineer to oversee the fabrication and to ensure that all dimensions are correct once the circular staircase is strung up in the air. These types of stringers take much longer to complete, which in turn causes the staircase to be more expensive than a staircase designed with consistent pitch, but the aesthetic benefits may make the increased cost well worth it.

Regarding the design and fabrication of circular stairs, please see the Chicago Metal Rolled Products easy-to-use and powerful Stringer Calculator. It’s likely to make your life easier by providing quick and accurate computations, improved communication, and increased quality.