A variety of methods can be used for bending stainless steel tubing. If the bend has a large radius, the tubing can be curved with three-roll benders (also called section benders, profile benders, or angle rolls.) If the bend has a tight radius, the tubing can be bent on a rotary-draw bender through a process called mandrel tube bending.

Both welded and seamless tubing can be curved. When the desired radius is very tight, seamless usually bends better.

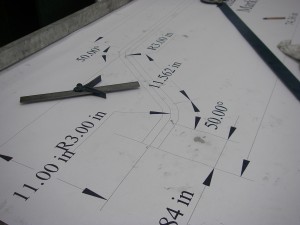

Recently we bent 8 pieces of 304 seamless stainless steel tubing 1.5 OD x 0.083 wall (14 ga) to a 5.25in inside radius with 81 degrees of arc and with 6in tangents on each end. These are prototypes for a vacuum pick-up tube system in a food processing plant.

Since the application of bent stainless tube often involves products for the pharmaceutical and food industries, care must be taken to avoid carbon contamination of the steel. The machinery and tooling should be cleaned and prepared to avoid such contamination. Furthermore, care should be taken to avoid having metal strapping in contact with the stainless parts. Cardboard, wood or plastic can be used to protect the tubing during transit.

After bending stainless steel tubing, a nut and sleeve can be slid over the ends which then can be flared. Process piping is often supplied this way. For example, 316 seamless stainless steel tubing 1.5 OD x 0.065 wall (16 ga) was bent with two 90 degree bends into a flat-back U. The ends had a 37 degree JIC flare. JIC (Joint Industry Council) fittings are widely used in fuel delivery and fluid power applications, especially where extremely high pressure is involved. Other tubing of the same size and grade was bent with an offset.

A full size template was made to allow for 100% inspection of the prototypes.

The pictures below show the final product which in this case will carry hydraulic fluid.