Engineers are constantly striving to improve their designs and this is true for those who design antennas.

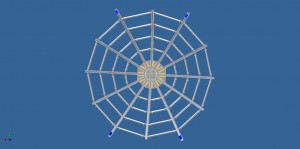

The requirement: 3 segments of 16 x 8 x 0.375 rectangular tube curved the hard way (i.e. x-x axis) to a 63ft 7.89in inside radius with 30ft of outside arc.

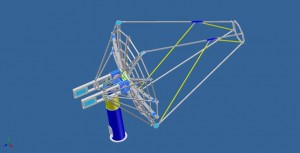

The application: curved tubes to support a dish for a prototype antenna on top of a mountain in Namibia. If the prototype, which was to be assembled and tested in Berlin, Germany, performed well, a number of full-scale structures, including the curved shaped antenna supports, would be built.

The new design was expected to be superior to older designs in two ways: rigidity and ease of installation. Previous designs incorporated straight struts to support the curved dish of the antenna: the new design incorporated the curved rectangular tubes which provided the extra beneficial rigidity.

Furthermore, previous designs required considerable welding in the field whereas the new design allowed for more in-shop fabrication and bolted connections in the field. You can imagine the difficulties involved in bringing certified welders to perform stringent welding procedures high on top of a mountain in Namibia. The new bolted design would make for ease of installation.