When someone from Chicago’s Museum of Science and Industry, the largest science center in the Western Hemisphere, asks about bending aluminum tubing, any metal fabricator familiar with the museum would surely ask about the application–if not out of curiosity, at least to further define the requirements.

A hallowed tradition at the museum this time of the year is its Christmas Around the World, a celebration that extends back to a 1942 salute to the Allied nations in World War II. Today fifty Christmas trees are festooned to reflect holiday customs from around the globe.

Additional decorations include lit-up garlands hanging from the massive marble columns at the center of the building. That’s where the aluminum tube bending comes in. The requirement was for 8 each, 1 x 1 x .125, 6063 aluminum square tubes rolled to a 2ft 4.5in inside radius with 180 degrees of arc, saw trimmed, and for 8 each pieces of .5 x .5 x .065 square tubes rolled identically except with only 6 inches of arc length. The smaller tubes function as sleeves to connect the larger tubes and make full rings.

Assembled, the rings function as column covers to hang the garlands on the marble columns.

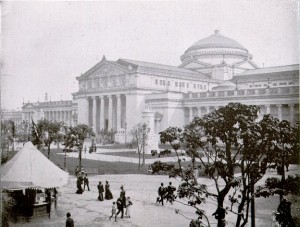

Since no one had previously measured the diameter at the top of the columns, the designer made the rings a little larger to ensure they would fit. After all, it was not clear what the tolerances would be on these columns built for the only remaining building from the 1893 World’s Columbian Exposition.