Reversed curved bending of beams is complicated to produce accurately and with minimal distortion. Reverse curve bending is where a steel section is curved to a radius in one direction and then is curved to a radius in the opposite direction. An “S” is an example of a reverse curve.Chicago Metal Rolled Products has done numerous projects with reverse curved steel beams, rectangular tubes, square tubes and pipe for many of our customers, whether fabricators, contractors, artists, engineers or architects.

One example of our reversed curved beam bending projects is the Ratner Athletic Center at the University of Chicago. Chicago Metal Rolled reverse curved 310 tons of W33 x 169 beams the hard way for the roof. The General Wayne Downing International Airport in Peoria, Illinois had 36 tons of square tubes, rectangular tubes, and beams curved the hard way that were also curved with a reverse curve. Both of these projects are examples of beams and rectangular tubes that were rolled hard way with a reverse curve.

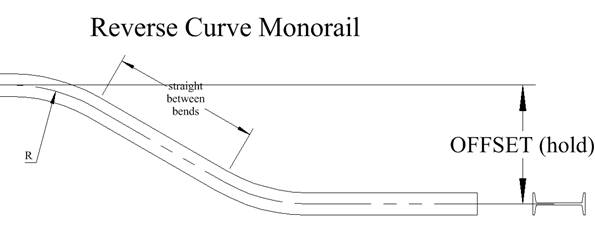

We have also worked with fabricators on resolving issues with reverse curved steel beams rolled the easy way. This application is typically used for monorail systems, and it is usually the offset which is most critical. Typically these are detailed with a splice. Being able to reverse curve these steel beams accomplishes the same thing without a splice. This is cost effective in that there is no splice, no testing of welds, and no worries. The process to produce a reverse curve is time consuming and costly, but it is often the better option when a structure or system is designed with a reverse curve bend.