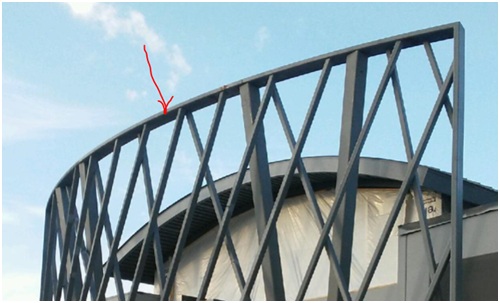

Just a few months ago we rolled a couple rectangular steel tubes and several square steel tubes for a decorative facade at the FMA’s new office complex. Since most of the tubes were exposed, the main concern was a distortion of the material.

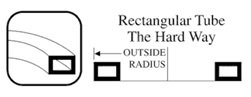

For this particular project, the two rectangular 14 x 4 tubes needed to be rolled hard way to a 50ft 6in outside radius.

The original design called out for 1/4“ wall thickness but after analyzing our extensive data on projects with similar tube sizes and requirements, and keeping in mind the customer request for no or minimal distortion we, decided to increase the wall thickness to 3/8”. In many projects with this size rectangular tube rolled hard way the 50ft 6in outside radius is large enough to achieve perfectly good rolled pieces with only minimal distortion. But because of the exposed nature of this installation we took special care and attention to produce perfectly smooth parts.

You can judge for yourselves in the photo below.

Our value engineering decision to increase the wall thickness of this tube, which allowed us to produce exceptional, distortion free pieces for our customer, came from over a 100 years of our accumulated expertise (since 1908) in the rolling and bending steel tubes, pipes, angles, bars, channels, tees, sheets and plates. We can help and guide our customers to make more suitable design choices for their rolled parts.