Have you been to the retailer Costco recently? If so, you might have indirectly contributed to funding a new museum in Union City, Tennessee. You may have noticed that many of their goods bear the Kirkland brand. Well, the Kirkland family started Costco and later founded the Robert E. and Jenny D. Kirkland foundation. That foundation financed a $100 million project in Kirklands’ home town of Union City, and construction began on The Discovery Park of America in 2008. It is designed to be a fun, interactive, and educational park experience for children and adults.

The Discovery Park of America sits on over 50 acres. Outside, there are gardens, a hillside amphitheater, and historic displays. Inside, there are 100,000 square feet of exhibits focusing on nature, history, science, art and technology. Highlights of these exhibits include a simulation of the 1811-12 earthquakes in the region, a 20,000 gallon aquarium, dinosaurs, Native American artifacts, military equipment, as well as a 60-foot replica of a human body with a 30 foot slide.

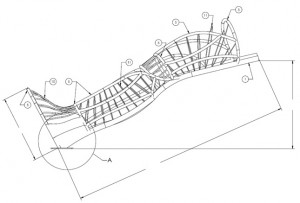

It is for this giant human body that Chicago Metal was contacted. The body required several thousand feet of steel bar and steel pipe curved to various radii to form a steel exoskeleton of the human body. The complex design required polished 3/4″ solid rounds, 1″, 2″, 3″, 4″, 5″, and 6″ pipe as well as 8″ x 6″ rectangular tubes curved to multiple radii against the strong (x-x) axis.

Chicago Metal Rolled Products and its customer agreed on a plan: Chicago Metal would roll several pieces to single radii, and then the customer would cut, twist and weld them together to simulate the sections with multiple radii. The customer made a mockup of individual “ribs” for each body part to ensure that the pipes were placed accurately. Chicago Metal Rolled Products would roll pieces in releases and deliver to the customer–in a timely fashion–all the pipes they needed of various sizes for each section of the body.

Surprisingly, the most challenging portions of the job involved the tiniest pieces. 3/4″ round bar was required for loops that ran through the giant human’s body. However, these weren’t standard shapes or even standard ellipses. The customer was originally planning on having Chicago Metal roll coils and then use heat to force the pieces into place. Shapes such as these were required:

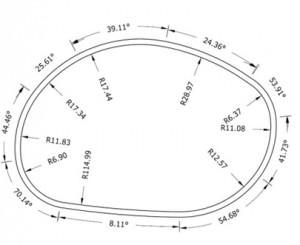

There would be quite a bit of labor and forming that would go into creating this shape from a coil or circle. Luckily, we had recently acquired a new CNC bending machine capable of bending multiple-radii pieces fairly quickly. When the customer sent us drawings of their pieces broken up into arcs that closely approximated their needs, we were able to supply them pieces that significantly cut down on their fabrication time:

Over the weeks, the body parts slowly began to come together. Here you see a welder at the customer’s shop attaching one of the loops inside the human’s head:

Our customer then took subassemblies of body parts from their shop in Chicago to Union City where they installed them several months ago. All that was left until the public got to see it was for the remainder of the museum to be completed. The grand opening recently took place November 1st, 2013.

Discovery Park’s mission is education: “To enhance children’s and adults’ educational experiences and to inspire them to reach their full potential.” Before the Discovery Center even opened, it began to achieve its mission by pushing Chicago Metal Rolled Products to “see beyond its current level of knowledge in many areas.”