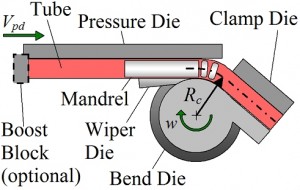

A wiper die is a tool in a rotary-draw-bending machine set up that prevents the deformation in the form of wrinkles that occurs when the material exceeds its elastic limit and sets in the curve. As the pipe is drawn into the bend, it becomes plasticized at the point of bend. The plasticized material behind the line of tangency flows into the curve of the bend die cavity sweeping away from the back tangent of the pipe. Upon completion of the bend, if this deformation exceeds the elasticity of the piping material, it will set as a hump or a series of small humps at the end of the bent pipe. Attaching a wiper die in the gap between the bend die and the pipe stops the deformation by blocking the flow of the material.

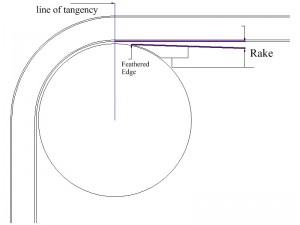

The essential feature of a wiper die is the feathered edge, which prevents the hump from forming and setting into a wrinkle. The design of the feathered edge is a knife-like edge formed by the convergence of the pipe cavity with the sweep of the radius face. Precision machining of this edge is key for good performance.

The key setting for the wiper die is rake. Rake is the maximum angle relative to the pipe centerline at which the wiper die can be set before the terminal hump forms. A wiper die can be raked, meaning the feathered edge is angled away from the line of tangency to block the flow of material just before it passes the point of elasticity. A wiper set at a zero-rake angle blocks the flow of all the material, and the resulting friction accelerates wear.

Aluminum-bronze and alloy steel are the most common materials for wipers. While steel offers good durability under the right circumstances, it galls due to friction and adhesion between the surfaces of the wiper and piping when used on steel tubing, especially stainless steel.

Wiper dies are available in one piece construction and inserted versions. An inserted wiper die consists of a disposable feathered edge, the wiper insert, and the wiper holder. The inserted wiper offers ease of use and reduced cost over the traditional, one-piece, solid, wiper die and can be used in all applications except those requiring zero-rake-angle bends.