Bending steel is defined as deforming steel around a straight axis. We use force to manipulate steel until it reaches a desired angle or shape. The difference between bending versus rolling depends on the radius. For larger radii we call it rolling, and for smaller radii we use bending. In this post, we’ll be focusing on bending plate.

Here are several key factors to take into consideration for the bending of steel plate:

Material Elasticity

Material tends to want to bend back to its original shape – this is commonly known as “spring back”. Every piece of material has to be evaluated and taken into consideration when bending. In some cases, the dies used to roll the material will bend the material further than the desired radius, but the over bend will be compensated by the material´s spring back.

Curvature Radius

The curvature radius has an important impact on thickness variations. One bend with no inside radius could imply material fractures and we should always avoid this kind of bend. Below are two examples on how stretching from press compression relates to thickness reduction:

- If the radius equals the thickness of the steel plate, the stretching of the material due to the tightness of the bend causes the plate thickness to decrease up to 20%.

- If the radius equals up to 5 times the thickness, the material does not stretch nearly as much and material thickness decreases less than 5%.

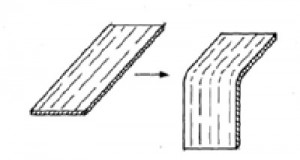

Bending Direction

The bend must always be performed perpendicular – or at most 45-degrees – to the grain lamination direction. This will increase bent resistance and reduce the risk of fractures.

We provide fast, free quotes for all our plate bending services. Contact us today.