A concern in bending long lengths of steel is how much they slump during handling.

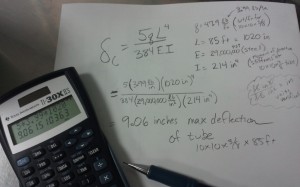

Consider, for example, a 10in x 10in x 3/8in x 85ft square tube picked up from both ends (simply supported beam model). This extremely long tube with a relatively thin wall will sag under its own weight about 9 inches! That’s 16 times more deflection than a piece 1/2 its length. A “normal” stock length 42ft long piece will seem very stiff when lifted from both ends and will deflect only 1/2 inches, a sagging barely visible. Here’s the calculation:

Question: with 9 inches of deflection, will the curved steel tube come back to shape after we set it back on the ground?

Answer: Yes. It springs right back into shape once it rests on the ground again. The sagging tube is nowhere near its yield point, typically 50,000psi, because the outer face sees only about 3500psi of tension.

The same cannot be said about these curved steel plates pictured below. If these steel plates were picked up at the ends, they would sag beyond their yield point. When these pieces come in flat, 3/8in x 120in x 26ft long, special care must be taken when picking up even a single sheet. If picked up only from the ends, a plate would sag 120in and the stresses would exceed 56,000psi.

Knowledge of the properties of steel sections combined with experience in handling extremely long lengths of steel can overcome even the greatest challenges of handling both straight raw material and curved steel sections.