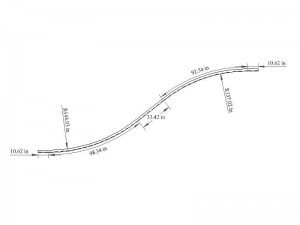

In many cases, a company that specializes in bending structural steel to a specified radius is able to roll steel channels to create an “S” curve. The “S” shape can be formed either by curving two pieces of steel and then welding them together or by rolling one piece with reverse curves.

Rolling two pieces of steel to create an “S” is easier to do because any deformation where the rolling starts can be trimmed off. Not so with the single piece construction. Care must be taken so that there is no deformation at the points where the curve reverses (or meets a straight tangent). Depending on the steel section, the radius and the orientation of the part (e.g. for channels, flanges in, flanges out, or the hard way), rollers may or may not have the ability to form reverse curves.

There are several benefits to one-piece construction. It can eliminate costly, full-penetration welds saving perhaps $1,500 per weld on a medium -sized structural steel member. It can have superior aesthetic value especially in AESS (architechtually exposed structural steel) applications. And it can result in a reduction in raw material required.

Sometime the requirement is for a straight section followed by a curved section and so on. In this case the cost of cutting and welding all the straight and curved sections together could be prohibitive. Single piece construction could be less expensive.

There may be some disadvantages to one-piece construction of an “S” shape. It may be too large to ship on a truck or require special permits for shipping. It may require closer tolerances to fit up in a fabrication shop because with multiple-piece construction, the welders can cut and trim to a greater degree.

A rolling shop should be able to respond to your inquiries regarding a reverse curve with information on 1. Can it be done in one piece? Or will multiple pieces be required? 2. Can it fulfill any AESS requirements? 3. Can the part(s) fit on a standard flatbed or will permits be required?