Mitsubishi Heavy Industries needed 750 tons of curved steel rail to support the retractable roof at Miller Park, home to the Milwaukee Brewers, 2011 National League Central Champions.

The required profile bending called for 2100ft of heavy rail to be rolled to a 600 ft. radius with a tolerance of +/-1/4in. The steel sections are about 9in wide, 6in tall, and 30ft long.

The original request from Mitsubishi was for a radius tolerance of +/-1/32 and an identical flatness tolerance. It developed, however, that the material, which was manufactured in Luxembourg and shipped through the Great Lakes to Chicago, could not be produced to that standard. Mitsubishi did an international search for companies to curve these steel sections and chose Chicago Metal Rolled Products to do the work.

After the +/-1/4in tolerance was agreed upon for the radius and for flatness, Chicago Metal held tolerances of +/-1/8.

Mitsubishi evaluated Chicago Metal’s performance: “I would like to thank all of the Chicago Metal employees for their quality of workmanship and their spirit of cooperation in the rolling of Mitsubishi’s rails for the Miller Park project.”

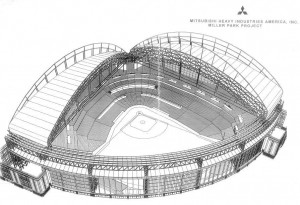

The only fan-shaped convertible roof in North America, the $50 million, 7-panel retractable roof opens and closes like a fan in about 10 minutes. The roof panels pivot mechanically on a fixed point behind home plate and 175ft above the playing field.

The roof is closed if game temperatures are expected to be below 60 degrees, or if rain or high winds are in the forecast.